- Name

- 600*600mm Factory Direct Sale Homogeneous Floor ESD Vinyl PVC Tile Flooring

- Model

- KM-PVC

- size

- 600*600mm

- Thickness

- 2mm 3mm

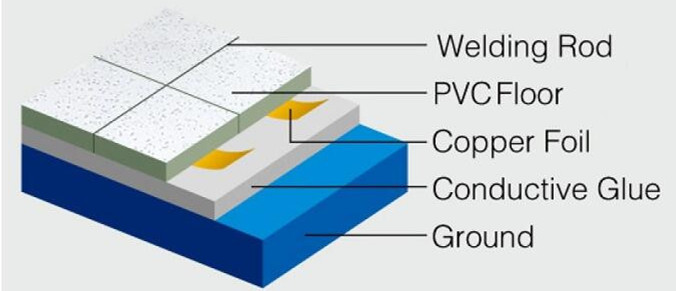

- Color

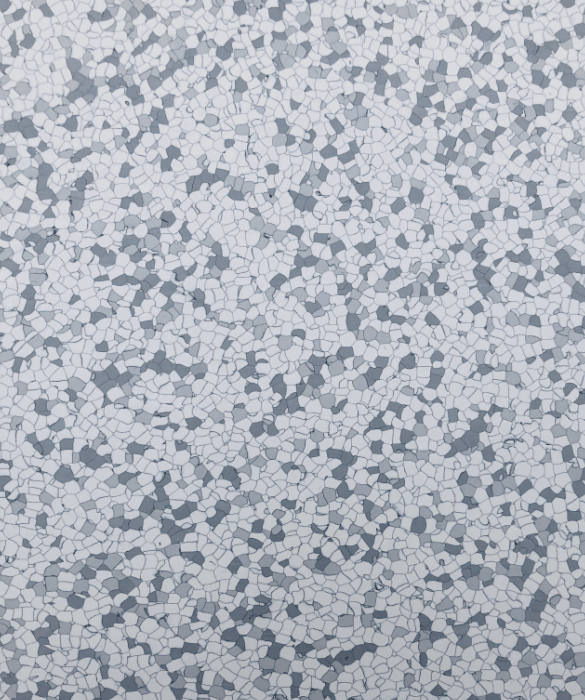

- White,Green,Grey,etc

- Feature

- Anti-Slip,Moisture Proof,Wear-Resistant,Fireproof,Waterproof,Soundproof,Anti-Static,Thermal Insulation

- Packing

- Craft Paper + Plastic Pallets

- DeliveryTime

- 15 Days After Receive 30% T/T Deposit

- Usage

- Household,Shopping Mall, Hospital, School, Theatre, Library,Computer room,Clean workshop,etc

Product Description:

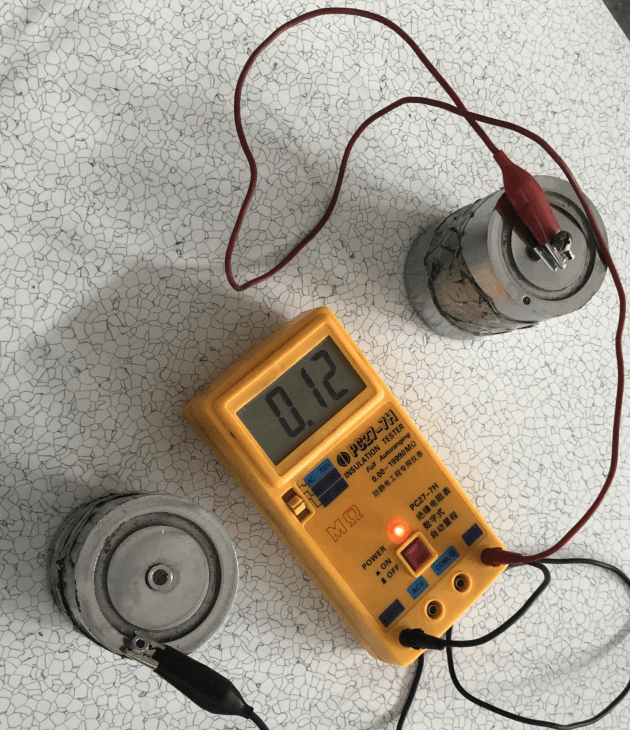

Electrostatic Discharge (ESD) flooring is also known as anti-static flooring, comes with anti-static performance (static-dissipative or conductive), and protects electronics from damage caused by static electricity.

The ESD flooring tiles are of high density, non-porous natural organic tile visual. They're manufactured by an extrusion process, mixing and pressing the pure PVC granules with carbon (graphite) fibers, and non-toxic color particles under proper pressure and temperature. Conductive elements are distributed throughout the flooring material, Thus they give ESD floors electrical conductivity, create an electrical pathway from the walking surface to the ground, and guarantee a permanent ESD performance.

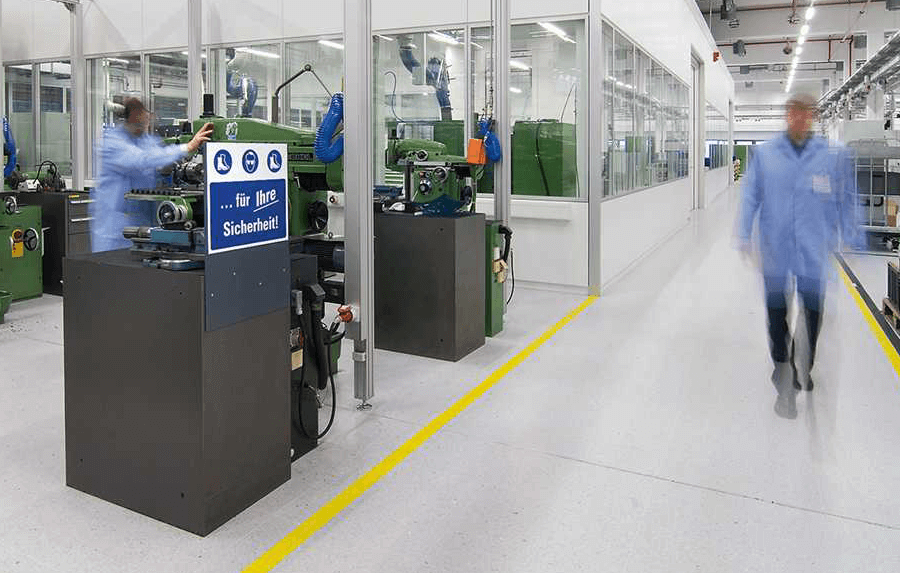

ESD vinyl flooring tiles are the choice of professionals for controlling electrostatic discharge in clean rooms, electronics manufacturing, computer rooms, repair facilities, or anywhere static-sensitive components are being used or manufactured.

| Item | Standard | Index |

| Size | EN426 | 600*600mm |

| 610*610mm | ||

| 900*900mm | ||

| Thickness | EN428 | 2.0, 2.5, 3.0mm |

| Weight | EN430 | 2.0mm, 3.8kgs/m3 |

| 2.5mm, 4.8/kgs/m3 | ||

| 3.0mm, 5.8/kgs/m3 | ||

| Surface Rresistance | DIN51953 | 104-106 Ω Conductive |

| ASTMF-1550 or NFPA99 | 106-109 Ω Dissipative | |

| Decay Tim | SJ/T10694-2006(VI<100V) | Equal 0.4S |

| Charge Voltage | SJ/T10694-2006(VI<100V) | Equal 70 |

| Fire Resistance | DIN 4102 | B1 |

| Combustion Properties | SJ/T11236-2001(<10s,FV-0) | Equal 0.35s Ifv-0 |

| Amount of anti-wear | SJ/T11236-2001(<=0.02g/cm3, 110r) | Equal 0.014 |

| Anti-wear Properties | EN660pt2 | Ten-T < 2.0 mm3 |

| Wheel Pressure | EN425 | No influence |

| Residual Concavity | EN433, DIN51955 | 0.03mm(2.0mm) |

| 0.035mm(2.5mm) | ||

| 0.04mm(3mm) | ||

| Dimensional stability | EN434 | <=0.1% |

| Color fastness | IDO105BO2 | At least 6 |

| Resistance to chenmicals | DIN423,DIN51958 | offers excellent resistance ask for special sheet |

| Impact sound absorption | VLI, ISO104, ISO717 | Approx 2dB |

| Standard for health care facities | NFPA99 | Comfirm to the requirement of NFPA99 in effect at |

ESD Tile Sizes

The popular and standard size is 600×600mm, 610x610mm, and 900×900mm.

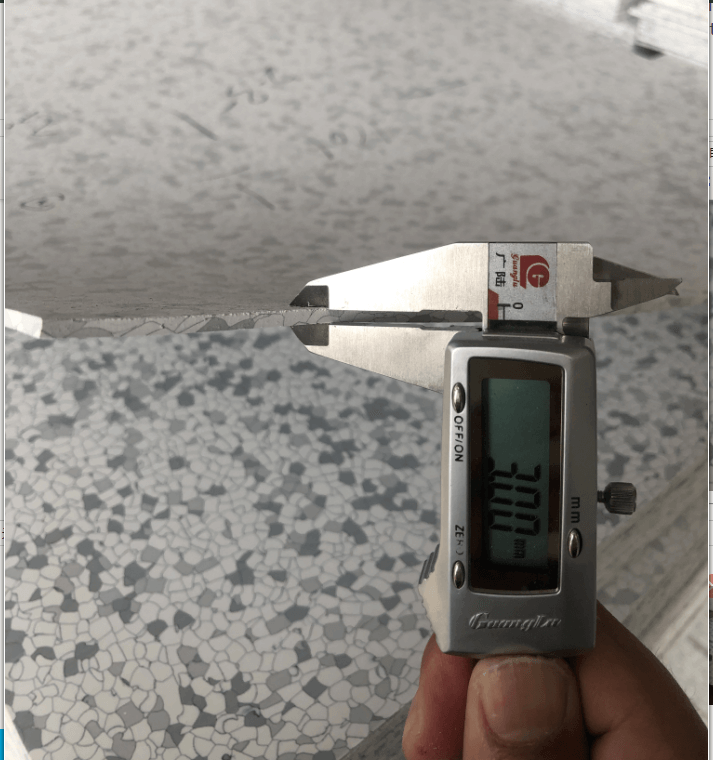

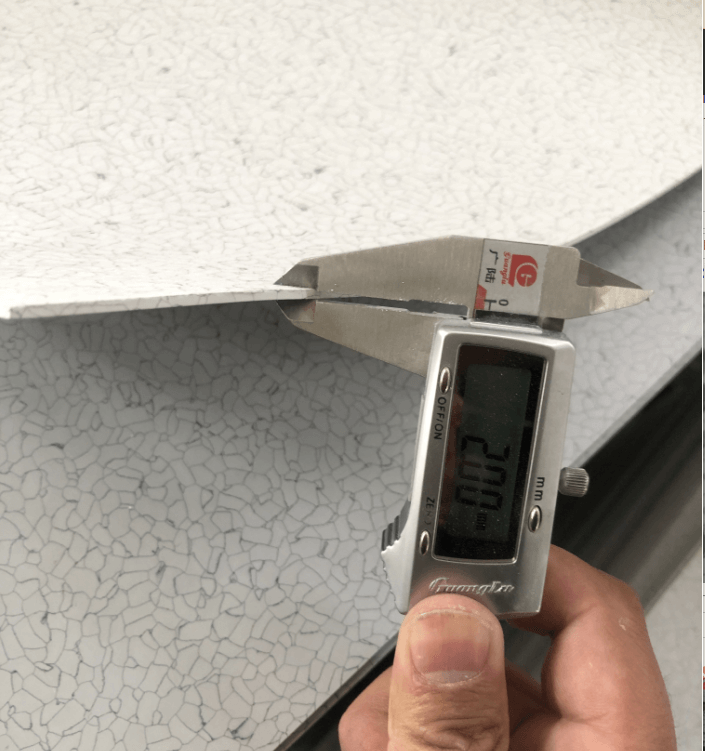

The thickness of the tiles is mainly 2.0mm, 2.5mm, and 3.0mm.

Weight: 3980g/m2 (2.0mm Thickness)

Detailed Photoes:

![DG[}Z0]KXZX6XLTT9U3C]$A.png DG[}Z0]KXZX6XLTT9U3C]$A.png](/uploadfile/images/20230213/6381188447707687215921082.png)

Application:

![V{48]OCUPMNP%`7WP1JWN5F.png V{48]OCUPMNP%`7WP1JWN5F.png](/uploadfile/images/20230213/6381188455942439162702775.png)

Product Parameters:

![D`T]8FJ4S3{I}7FZ09PBNFG.png D`T]8FJ4S3{I}7FZ09PBNFG.png](/uploadfile/images/20230210/6381163586888587537619559.png)

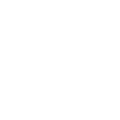

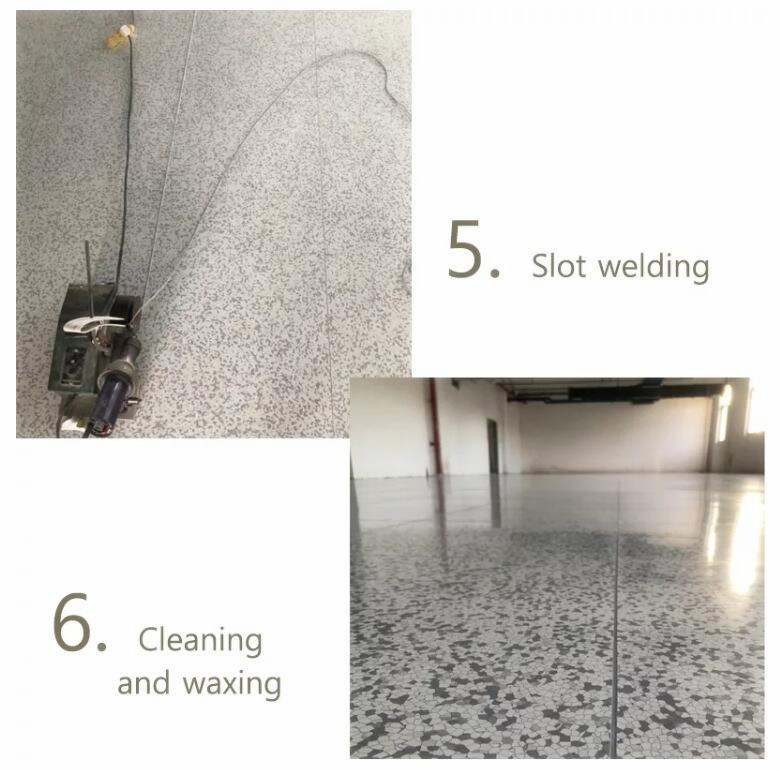

Installation Instructions:

Installation should be carried in accordance with local standards. Subfloor to be smooth, hard, clean and dry prior to

laying.Where applicable the subfloor must incorporate an effective Damp Proof Membrane. The material must be allowed to

acclimatize 24 hours before installation in a room temperature of between 18 - 24 degree.

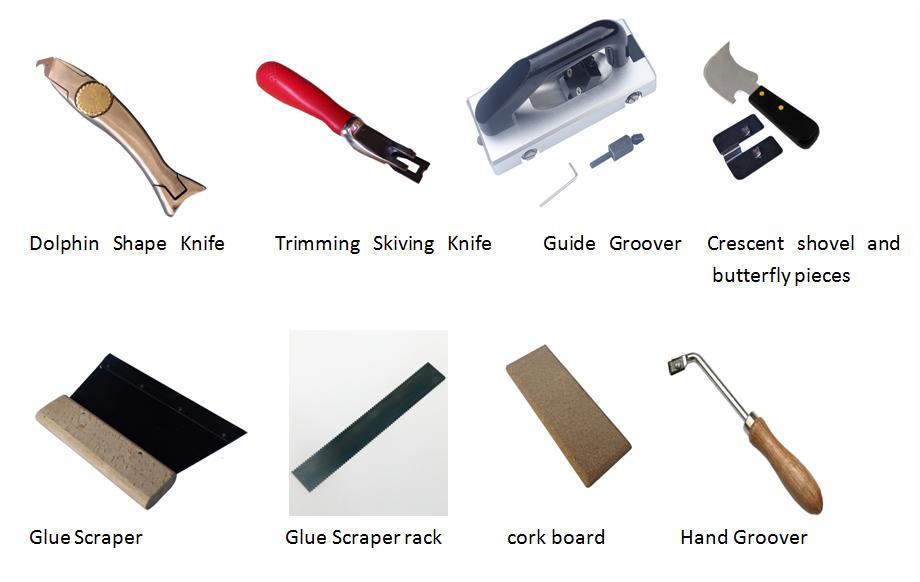

Floor Install Accessories:

Product Advantages:

Advantage:

(1) Products Property Anti-static PVC Vinyl Floor, permanent anti-static property. The products are widely used in the place of precise instrument and professional equipment, including electronics, clean room, computer room, hospital, telecommunication, airspace, etc.

(2) Environmentally-friendly Materials

Comply with ISO14001, using European advanced production technology. Insure the raw materials and production meet European standard.

(3) Durable

Anti-static Vinyl Flooring has excellent stability and wear resistance, meet the usage of all kind of public huge traffic site, durable, perfect stress resistance and wear resistance.